Exporting a geometry suitable for DRTF generation from Solidworks

Solidworks is one of the leading tools to design complete products as well as mechanical parts and assemblies. As such, it allows to work on the geometry at the maximum precision, keeping all the information in the same file.

In order to create a geometry that can be used to generate a DRTF, it is currently necessary to create a version of the file that consists of a triangulated mesh-like geometry.

In the tutorial below we show the workflow to create a simple extrusion object, create a mesh out of it, export it as .STL, then convert it to .OBJ. In the near future, we will allow to directly import STL files for DRTF generation.

Creating the object

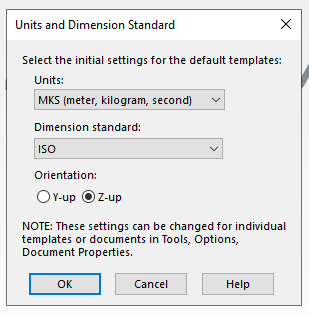

In Solidworks, we start by setting the units to MKS Z-up, since we want to model our geometry in meters and the simulation conventions assume that the Z coordinate is oriented upwards.

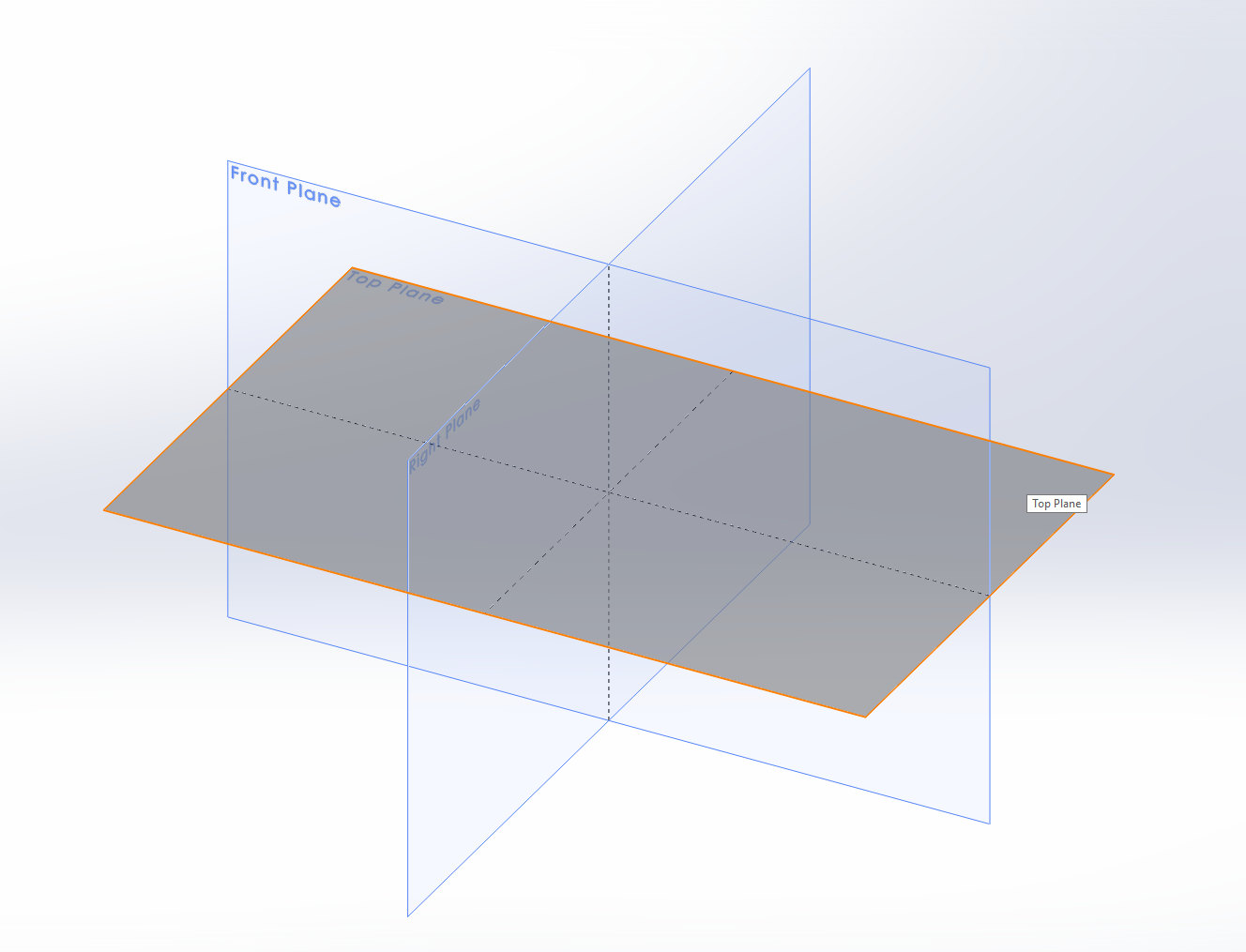

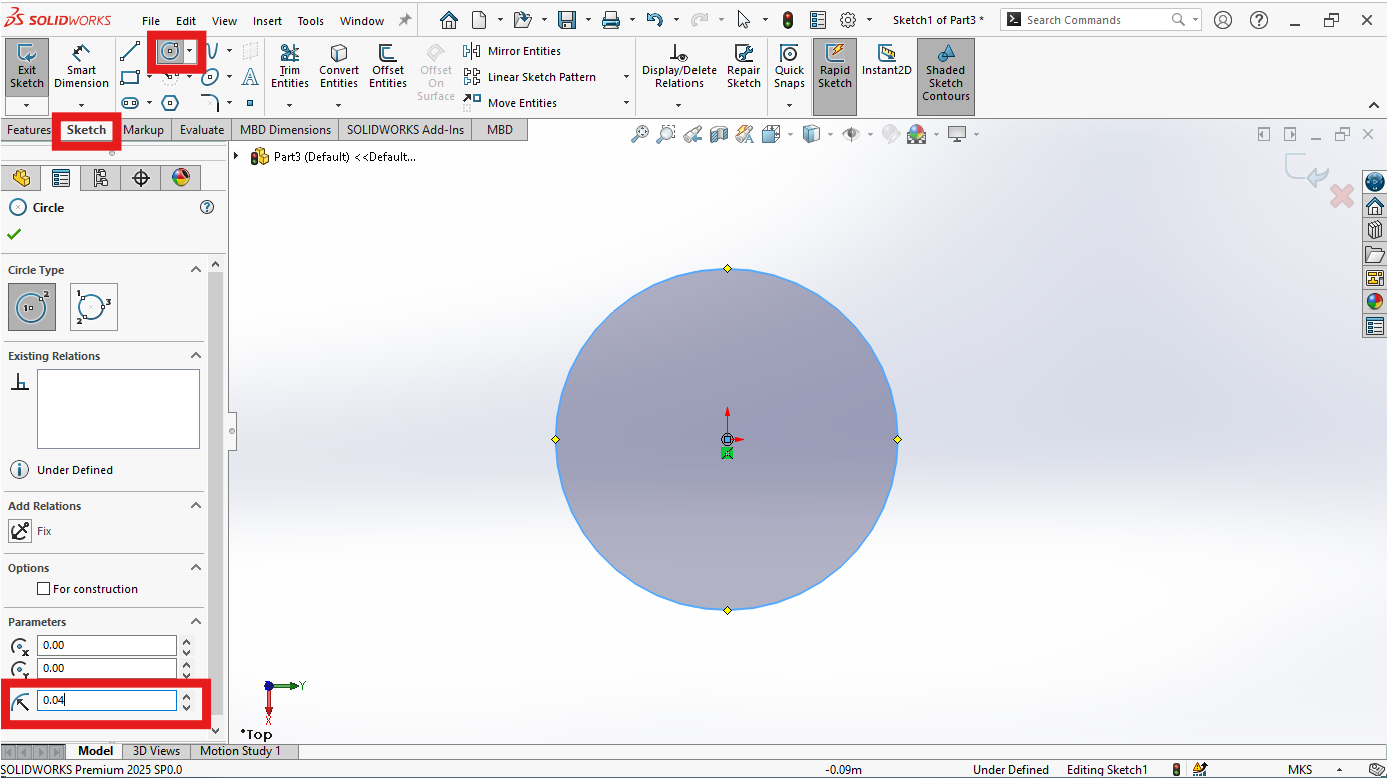

We then use one of the Sketching tools such as circle to define a generator geometry in the XY plane, that will be the base of our solid geometry.

We make sure that the circle has the center in the origin and its radius is 4 cm (0.04 m), as shown in the inspector.

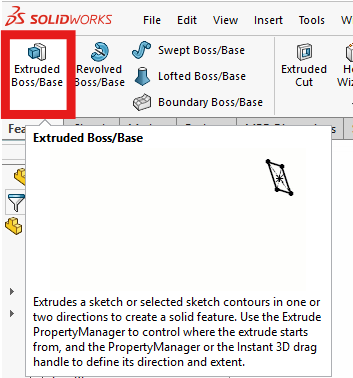

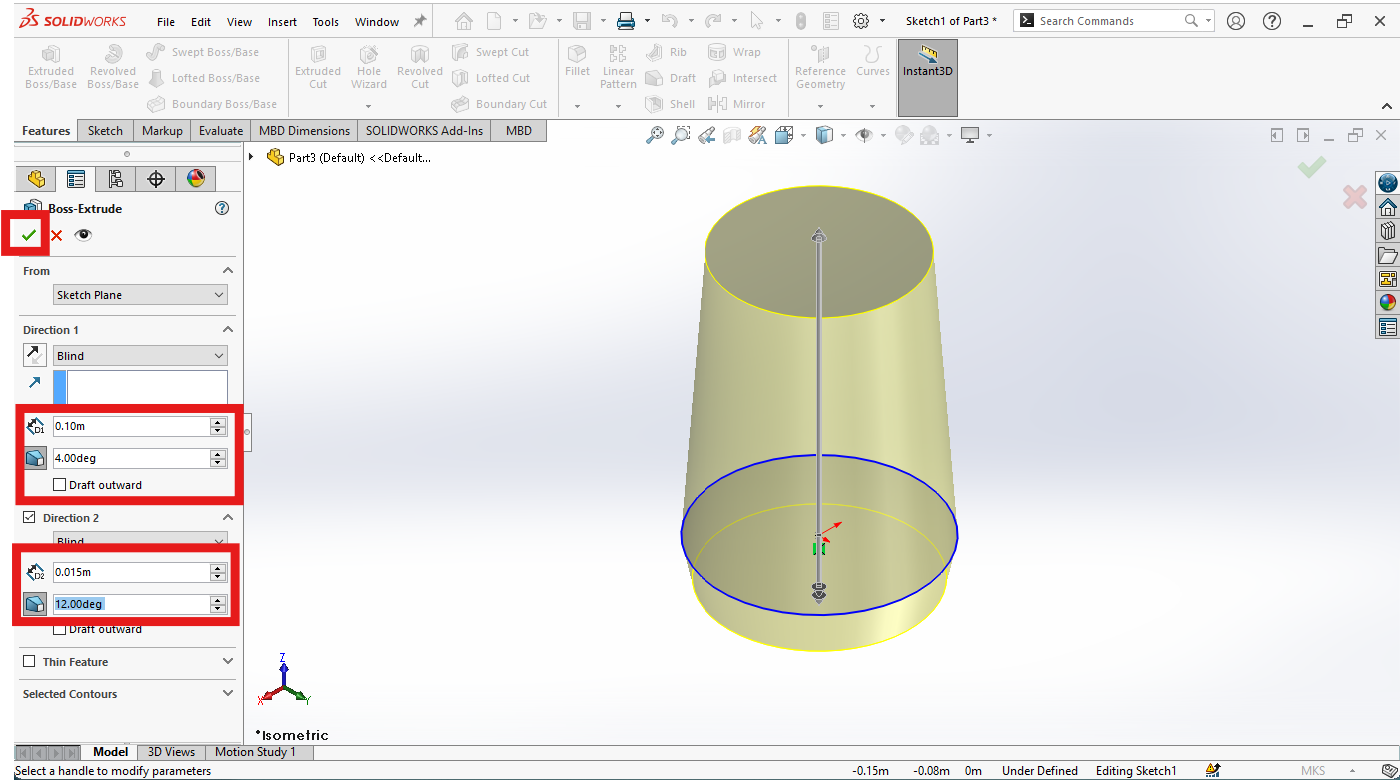

We then proceed with the modelling through the Extruded Boss/Base command in the Feature tab.

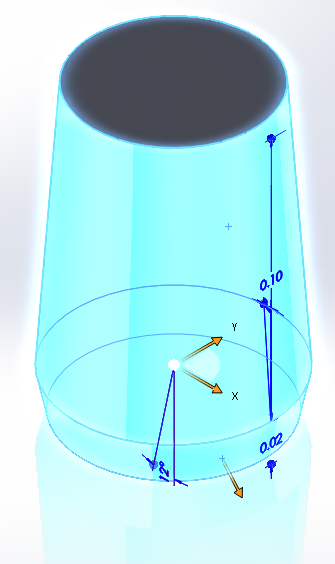

We set a direction, for example Blind, with a length of 0.1 m and we give a Draft angle of 4 degrees. We apply to the bottom extrusion a length of 0.015 m and a Draft angle of 12 degrees. We then confirm with the green checkmark.

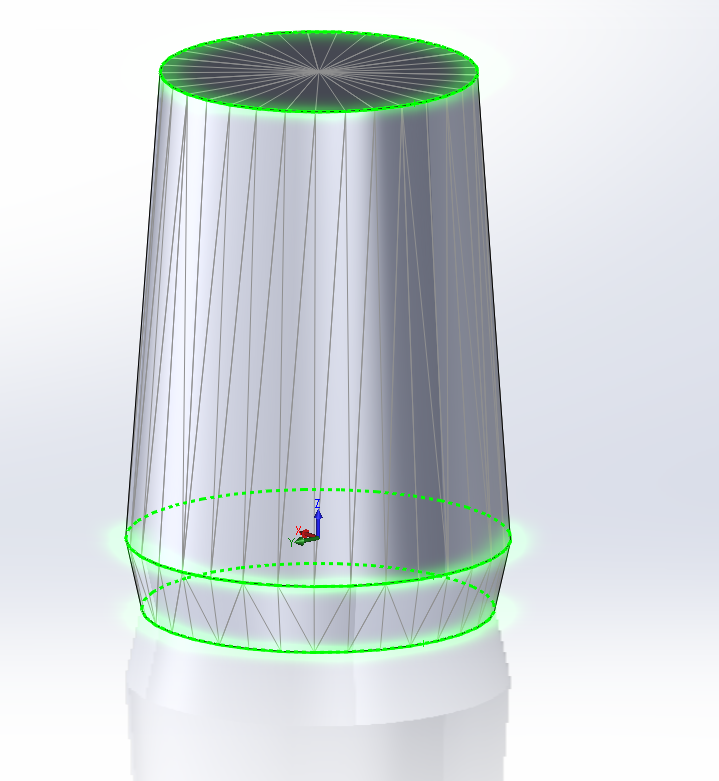

In the image below we can see our object with the parameters we have just set. Now we can save the file and proceed with the next step.

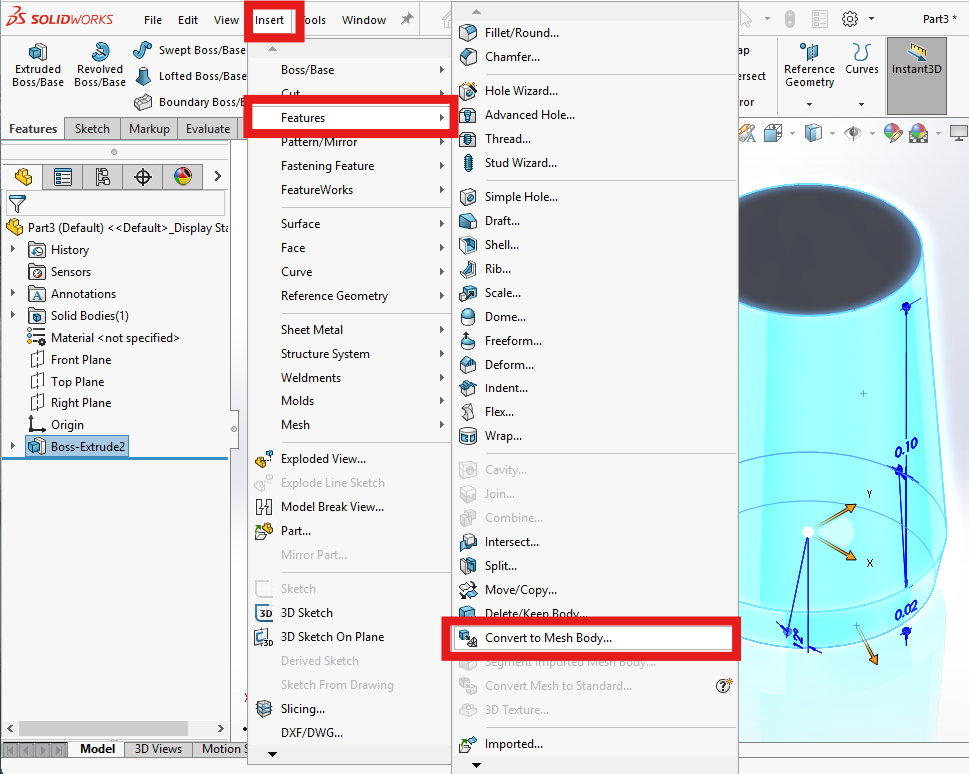

Creating a Mesh Feature

With all the object parts selected, we navigate to Insert > Features > Convert to Mesh Body.

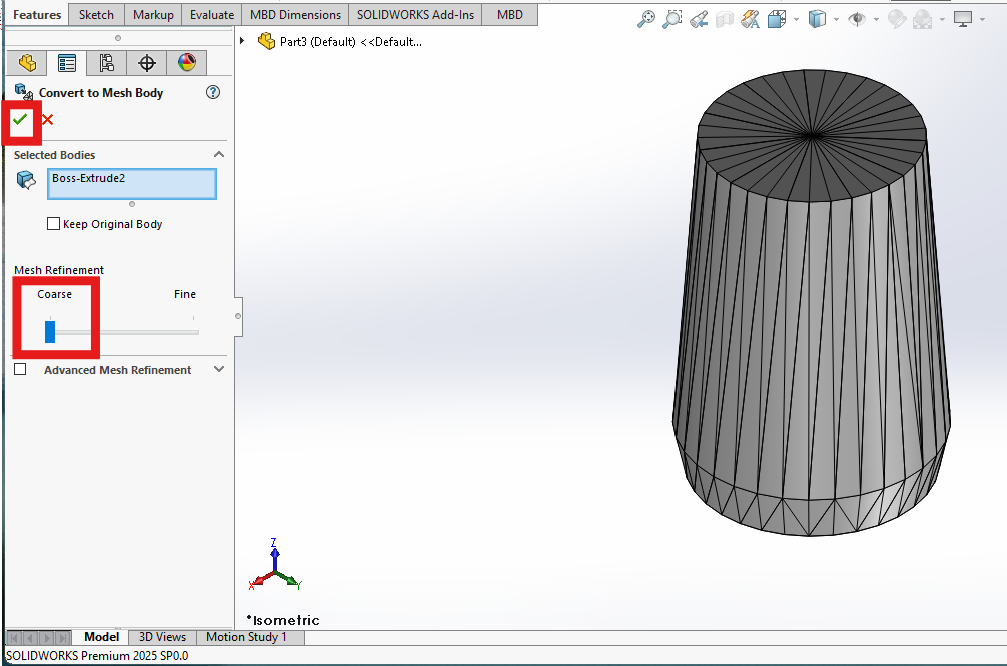

This will create a command where it is possible to select the body and choose whether to keep the original. In this case we assume that we are working on a copy, so we don't keep the original. We can either choose the mesh refinement on a generic slider going from Coarse to Fine, or select Advanced Mesh Refinement Options.

For this example, we recommend setting the options to the Coarser settings.

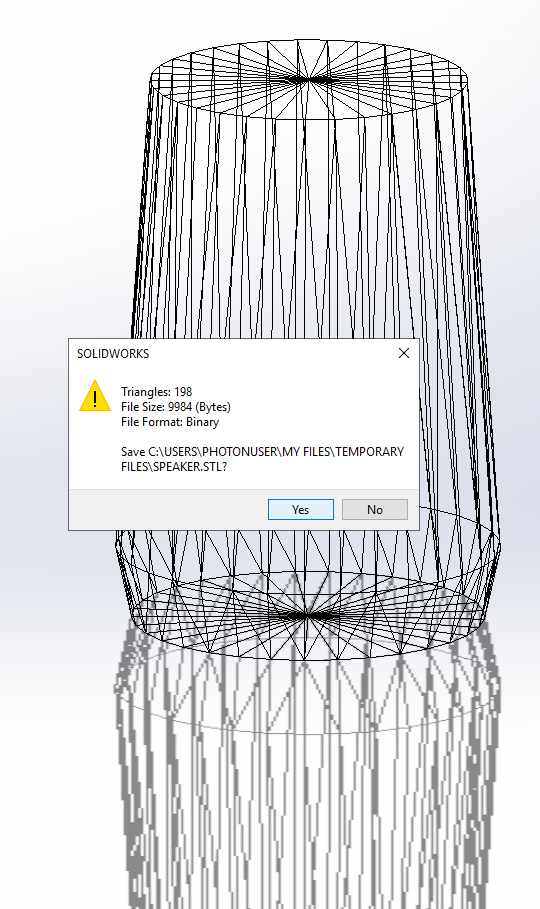

If we inspect the object we can notice how it appears made by triangles. The object can now be exported as STL

Exporting as STL

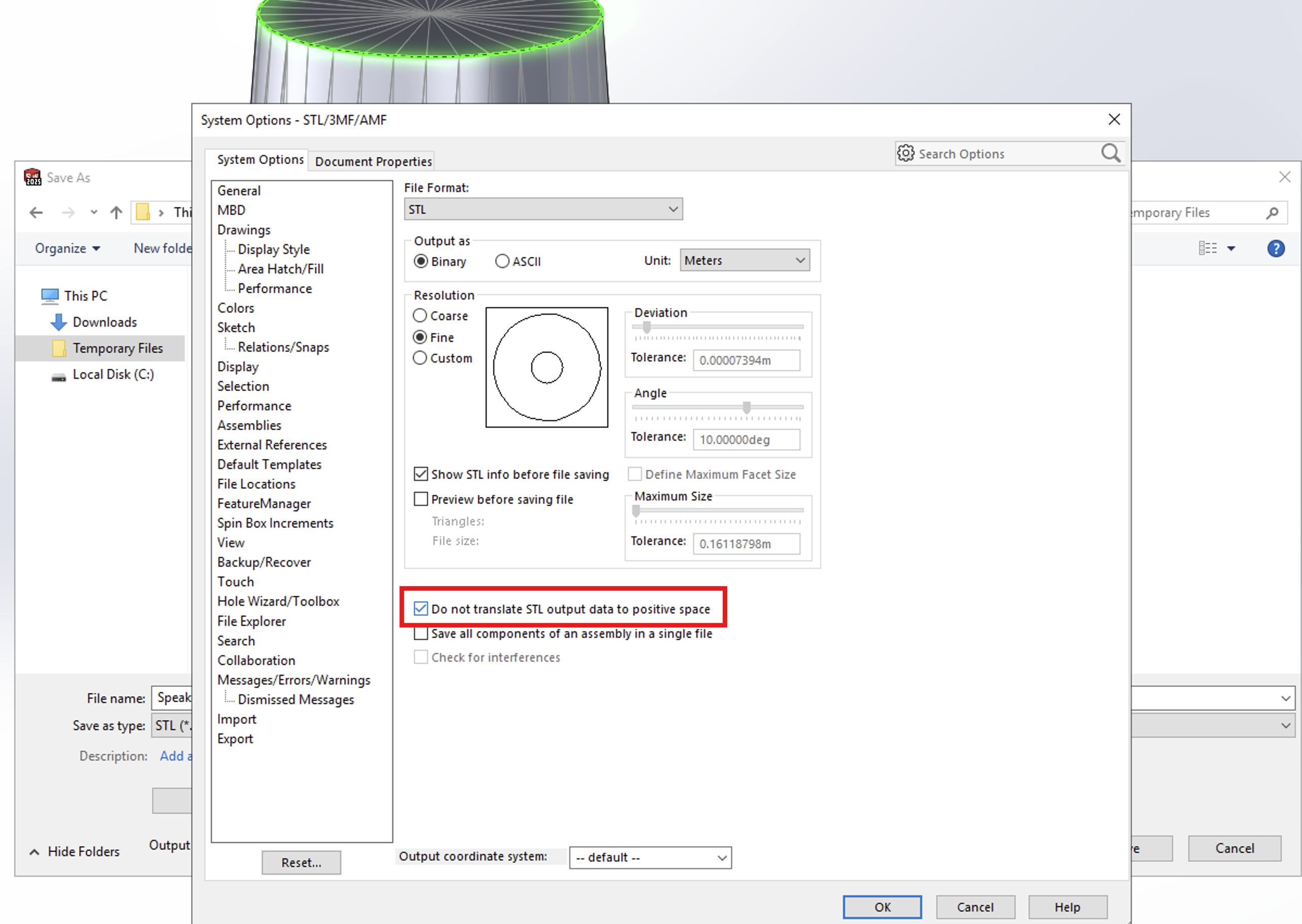

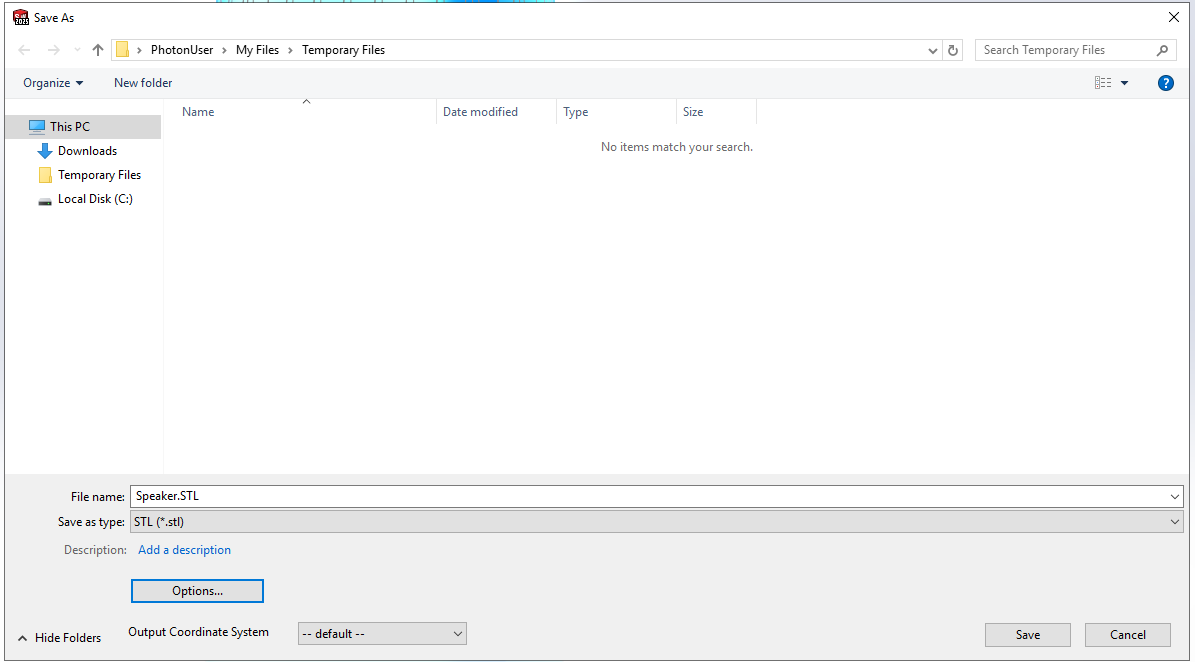

From File, we click Save or Ctrl+S and we select STL file format. There is a window panel where we can set additional export options. The parameter that we need to check is Do not translate STL output data to positive space, since this will otherwise move the object coordinates (this option can be handy when manifacturing).

It is also possible to control whether the object needs additonal processing, in case it hadn't been previously meshed. We recommend setting the export options to Fine. Units need to be in meters.

Converting from STL to DXF or OBJ

Once an STL output is saved on the drive, we need to convert it either to DXF or OBJ.

If the user has a native exporter to convert from STL to OBJ, this is preferrable, otherwise, it is possible to use online conversion services such as Convert3D. We tested the conversion from STL to OBJ with this tool.

Although Solidworks shows that it is possible to export to DXF, this works only for 2D drawings and is not suitable to generate 3DFACE objects, which is what the TrebleSDK needs when importing DXF files.

In the future, we will allow to import directly STL files.

This guide has been tested with Solidworks 3DExperience